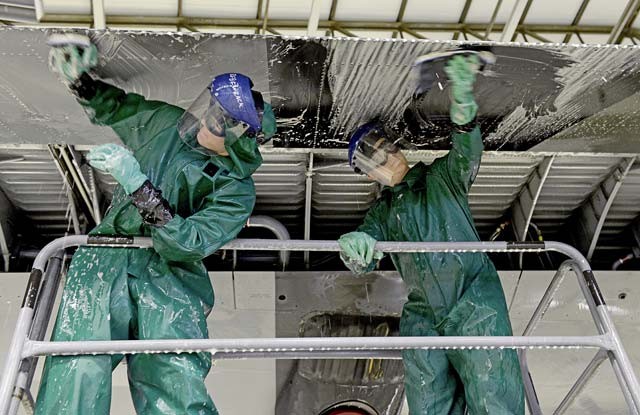

“Clean before applying paint” is a direction many people may disregard during a home improvement project, but they are words that are well-heeded by the members of the 86th Maintenance Squadron isochronal inspection section.

Proper washing and painting is crucial in maintaining the aircraft assigned to Ramstein.

“(It) is for corrosion prevention,” said Tech. Sgt. Andrew Kohn, 86th MXS ISO dock coordinator. “You want to get all the grime and grit that gathered while it was out.

“We don’t always land on international runways,” Kohn added. “We (often) land on dirt runways with rocks, so you’re going to get nicks and things wrong with your plane.”

For this reason, Kohn said they wash and paint the aircraft in conjunction with the regularly scheduled ISO inspections.

An ISO inspection is a scheduled, extensive examination of an aircraft to maintain its functionality and perform preventive maintenance. The inspections can vary in time and complexity, with inspections categorized as either A, B, C-1 or C-2 checks.

“The C-2 check, which is the most in-depth, is what we’re coming up on right now,” Kohn said. “Anything and everything that you have on this aircraft is going to be touched by us.”

This C-2 check marks the end of an ISO inspection period of the 14 C-130Js assigned to Ramstein. After this C-2 inspection, Ramstein will not be due for another one until 2020.

“For the 86th Airlift Wing, that means more reliability on the aircraft side,” Kohn said.

The inspections involve Airmen from multiple shops in the 86th MXS, but each aspect of the process adds value to getting the aircraft back into operations.

“I had never heard about having to wash an aircraft, and then I got here. In my second or third week I was told I was going to wash,” said Airman 1st Class Ryan Kuiper, 86th MXS aerospace maintenance apprentice. “It’s an experience I’ll never forget, that’s for sure.”

The Airmen have one day to get the entire aircraft washed. As such, Kuiper said the wash day can be long and physically taxing.

“It’s cool to see the plane go from dirty to clean,” Kuiper said.

Though the painting is mostly just touch-up spot painting, it is still an important method to prevent corrosion and extend the life of the aircraft.

Once the aircraft is washed and painted, it then officially goes into inspection, which is broken up into “look” and “fix” phases.

“They are very in-depth inspections,” Kuiper said. “The planes get taken apart and put back together.”

The ISO section typically looks for the items that would cause mission stoppage first, but they check everything from burned-out light bulbs to cracked airframes.

“You learn how things operate, what goes wrong more than others,” Kuiper said. “During the inspection, you learn why things are more important than other things.”

Kuiper said the inspection is better than the wash because, though they are still on a time crunch, they are allowed more than the one day that completing the wash requires.

Each C-2 inspection takes approximately two weeks to return the aircraft to operational status, but it all begins with a wash and paint job.